TEQUIO

3rd PRIZE

[bruno lopes, ingra tofetti, pedro feriotti, milena boccato hein]

sao paulo, brazil

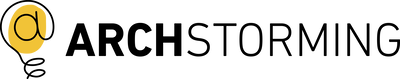

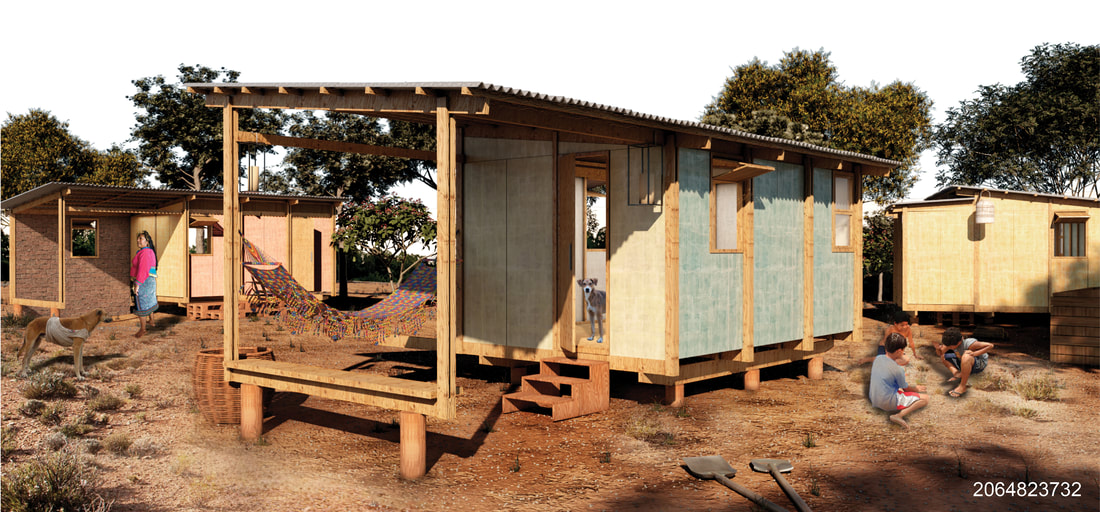

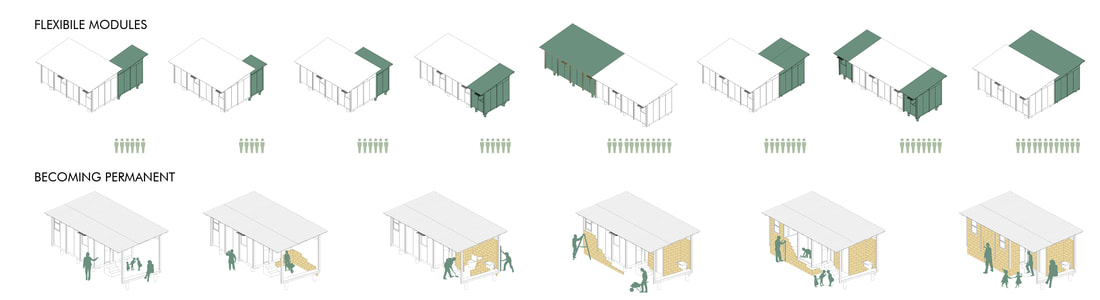

The proposal for EMERGENCY HOUSING MEXICO! aims to design a house that is uncomplicated in form, easy to prefabricate and fast to assembly, while creating a livable interior and keeping it affordable.

The design uses a building system that is similar to the actual, which allows for an easier transition from the old to the new design, using the same tools and machinery and not requiring any specific construction technique.

The construction system consists of a wood structure, mostly using 2x2" pine wood in triangular dispositions—a three-dimensional structure that is simple and has a high structural performance while reducing the amount of material used. The wooden structure is covered on its both sides: the exterior layer is made of fiber cement boards (as in the actual design) and the interior is covered in 1/8" triplay, a thin inexpensive layer of tripay that dramatically improves the aesthetics of the interior space. Between these two layers (1/4" fiber cement board outside, 1/8" triplay inside) that are separated by 2" (the thickness of the wood structure), a 2" layer of expanded polystyrene (EPS) is placed, completely filling the wall and solving another of the issues of the actual design: its thermal insulation. EPS is an inexpensive and ultralight (it is made of 99% air) material that offers high thermal and acoustic insulation and entirely surrounds the house, including walls, floor and ceiling.

The construction system is used to create the panels for the entire house, with minor variations:

- The flooring grid uses 4x2" wood pieces for structural reasons and substitutes the fiber cement boards on the outer layer for a hexagonal mesh, a very low-cost material that holds the EPS (which does not need waterproofing) in place.

- The roofing panels use a similar solution with the hexagonal mesh on the inside layer and corrugated metal sheet on the outside, which waterproofs the house and protects it from the exterior.

- One variation of the wall panels is used for the windows, where 1/4" clear polycarbonate substitutes the fiber cement board and the interior layer of triplay is not placed. The door uses a regular wall panel.

All of these pieces (floor, wall and roof) are prefabricated in standard 48x96" panels, easy to pack for transportation to site, light enough for two people to move them and concentrating most of the work on the prefabrication, reducing on-site assembly times and costs.

The design uses a building system that is similar to the actual, which allows for an easier transition from the old to the new design, using the same tools and machinery and not requiring any specific construction technique.

The construction system consists of a wood structure, mostly using 2x2" pine wood in triangular dispositions—a three-dimensional structure that is simple and has a high structural performance while reducing the amount of material used. The wooden structure is covered on its both sides: the exterior layer is made of fiber cement boards (as in the actual design) and the interior is covered in 1/8" triplay, a thin inexpensive layer of tripay that dramatically improves the aesthetics of the interior space. Between these two layers (1/4" fiber cement board outside, 1/8" triplay inside) that are separated by 2" (the thickness of the wood structure), a 2" layer of expanded polystyrene (EPS) is placed, completely filling the wall and solving another of the issues of the actual design: its thermal insulation. EPS is an inexpensive and ultralight (it is made of 99% air) material that offers high thermal and acoustic insulation and entirely surrounds the house, including walls, floor and ceiling.

The construction system is used to create the panels for the entire house, with minor variations:

- The flooring grid uses 4x2" wood pieces for structural reasons and substitutes the fiber cement boards on the outer layer for a hexagonal mesh, a very low-cost material that holds the EPS (which does not need waterproofing) in place.

- The roofing panels use a similar solution with the hexagonal mesh on the inside layer and corrugated metal sheet on the outside, which waterproofs the house and protects it from the exterior.

- One variation of the wall panels is used for the windows, where 1/4" clear polycarbonate substitutes the fiber cement board and the interior layer of triplay is not placed. The door uses a regular wall panel.

All of these pieces (floor, wall and roof) are prefabricated in standard 48x96" panels, easy to pack for transportation to site, light enough for two people to move them and concentrating most of the work on the prefabrication, reducing on-site assembly times and costs.